Description

Ryden Capital Engineering Limited is the leading supplier of fireproof cement also known as High Alumina Refractory Castable Cement in Nairobi Kenya, Kampala Uganda, Tanzania, Kigali Rwanda, Juba South Sudan, Burundi and DRC Congo. We have both medium Alumina Content(56% – 60% alumina content) and high Alumina content castable cement (90% alumina content) for various industrial applications in Eastern Africa.

Our Major Brands of Fire Cement are as below:

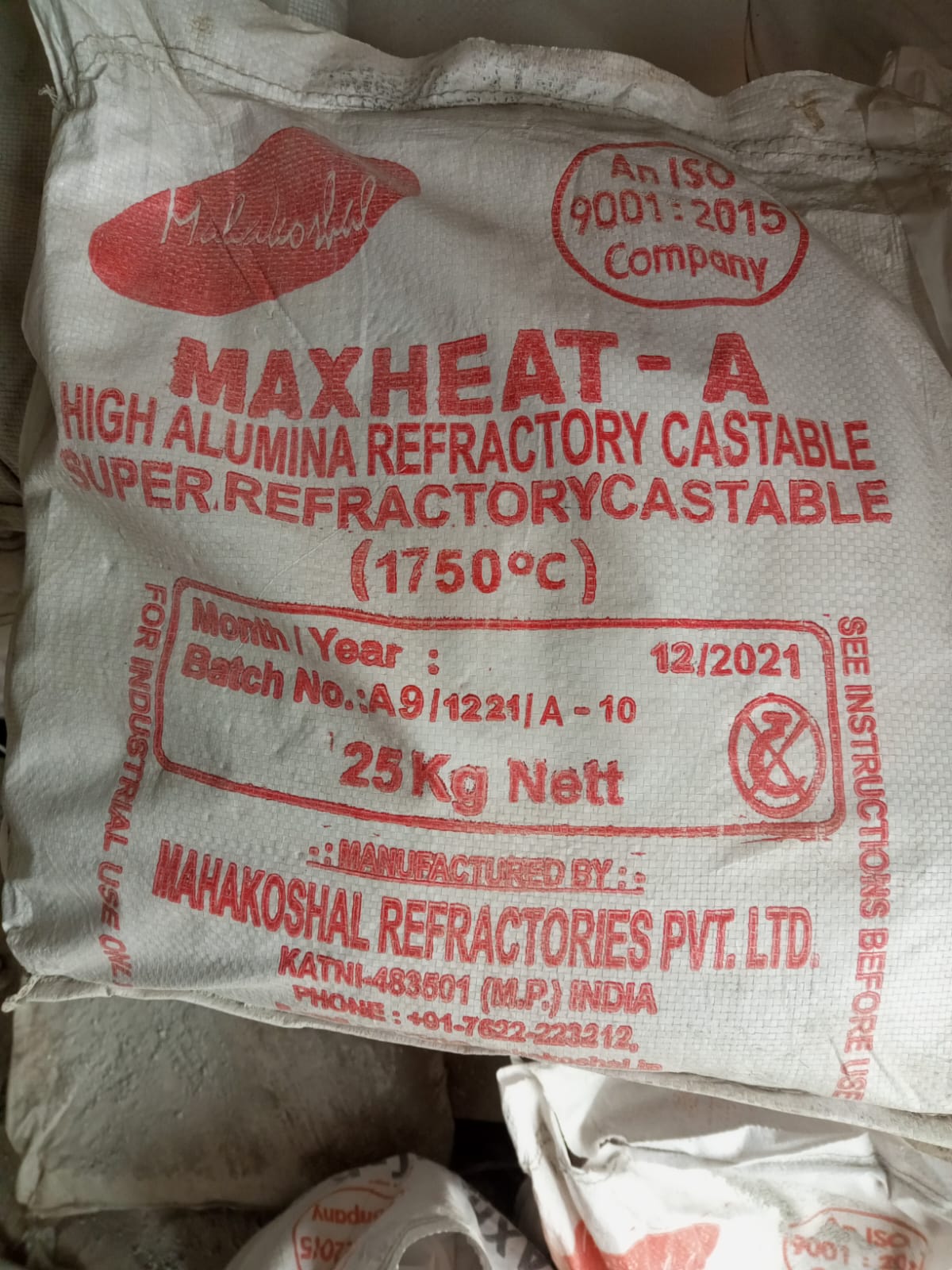

- Super Refractory Castable Maxheat A 1750 Degrees Celsius 25 Kgs

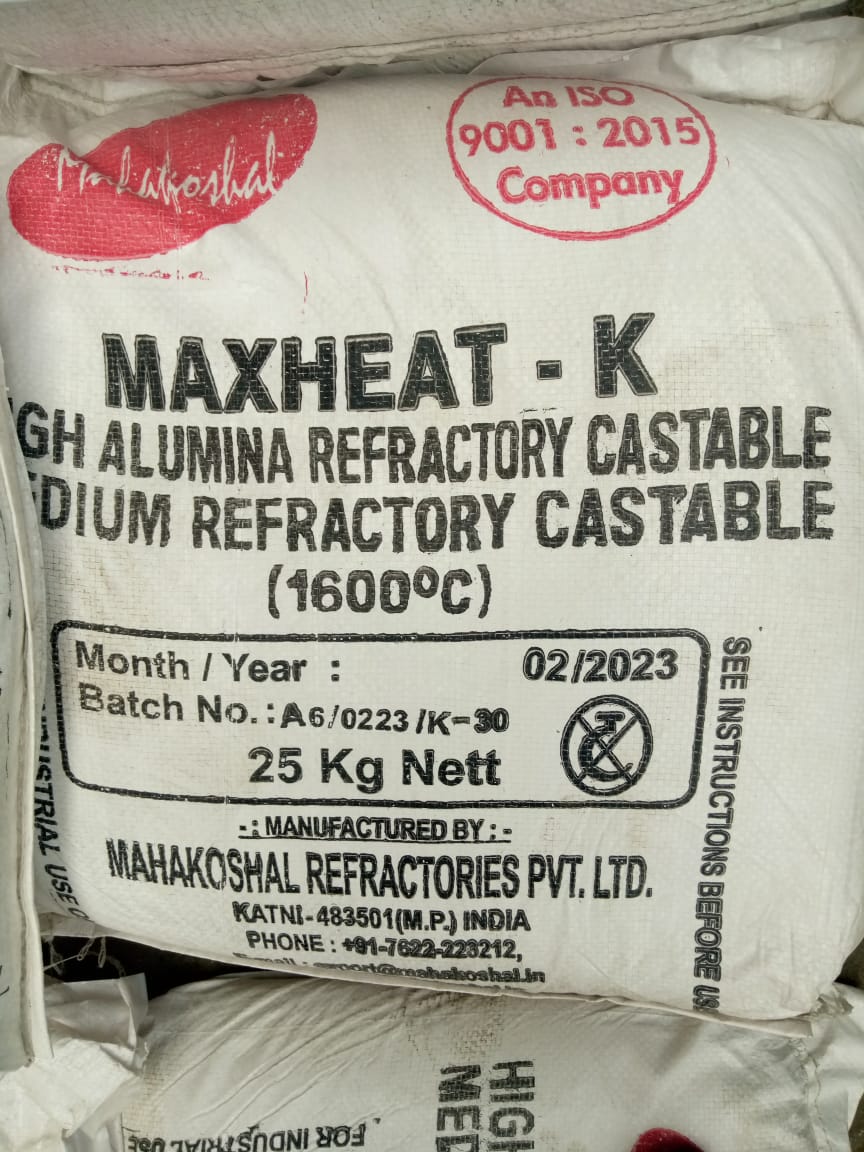

- Medium Refractory Castable Maxheat K 1600 Degrees Celsius 25 Kgs

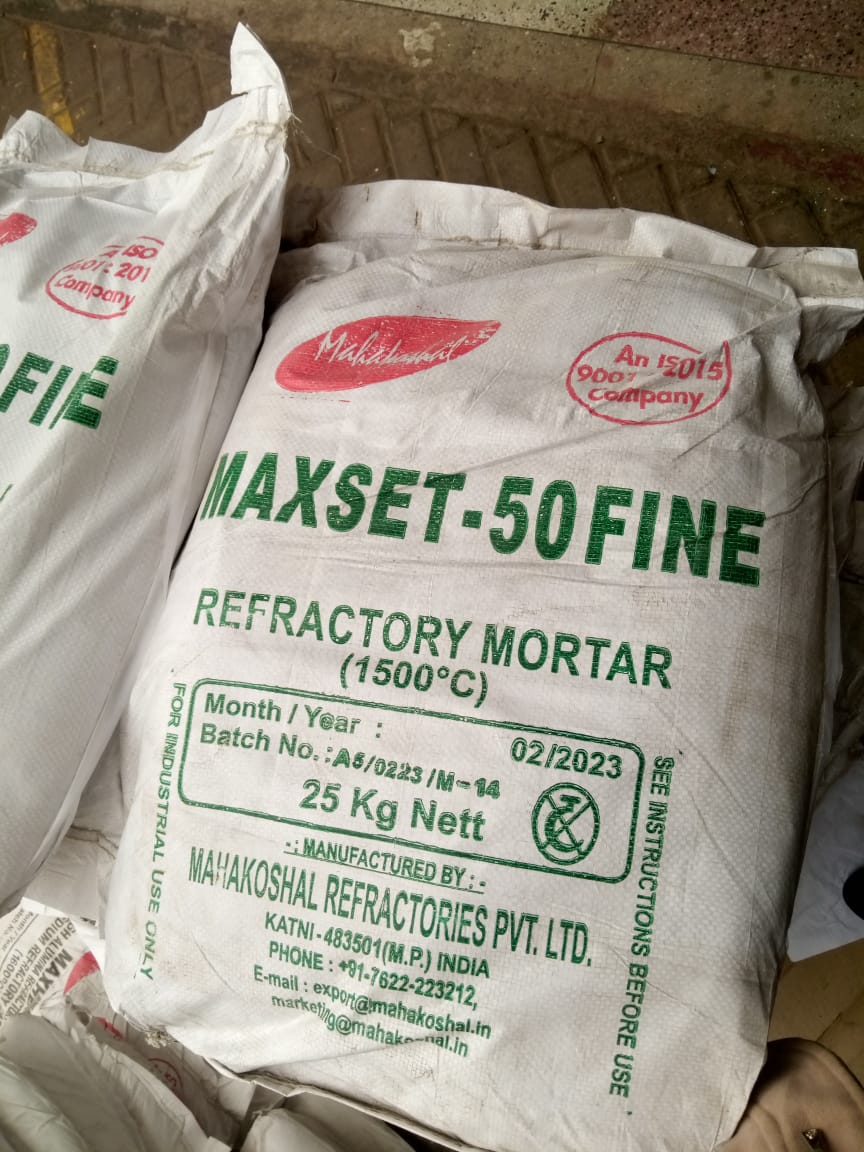

- Refractory Mortar Maxset 50 Fine (Fire Clay) 1500 Degrees Celsius 25Kgs

- Fondu Cement Fine Refractory Castable Max50 1000 Degrees Celsius 25 Kgs (Fast Drying Refractory Castable)

Get in touch with us to place order through +254 722 293 517 or email us via info@rydencapitalengineering.co.ke

Maxheat K 1600 Degrees Celsius

Refractory Mortar Maxset 50 Fine (Fire Clay)

Maxheat A 1750 Degrees Celsius

Fondu Cement Max50 1000 Degrees Celsius

High Alumina Castable Maxheat K 1600 Degrees

High Alumina Castable Maxheat A 1750 Degrees

Refractory Mortar / Fire Clay Maxset 5o Fine 1500 Degrees

Fondu Cement Max50 1000 Degrees

Refractory castables are premixed combinations of refractory aggregates, matrix components or modifiers, bonding agents, and admixtures. They are mixed with a liquid (usually water) at the point of installation and vibrated, poured, pumped, or pneumatically shot into place to form a refractory shape or structure that becomes rigid because of hydraulic or chemical setting.

The majority of refractory castables use calcium aluminate cement as the bonding agent though in recent years other bonding agents have also been developed. All castables have refractory aggregates and matrix components which allow their use to temperatures up to 1850 deg C.

- CONVENTIONAL DENSE REFRACTORIES

Conventional dense castables are created with high alumina cement, and can withstand temperatures from 1300oC to 1800oC. These refractory castables are great for common furnace applications, burner blocks, speciality muffle furnaces and boiler work. Resistance is a key quality that varies with the choice of materials, resulting in abrasion, thermal shock and slag attack. Casting and gunning techniques are the method of installing the materials. For the ease of castable placement, gunning materials and water are combined together at the gunning equipment’s nozzle. This is a great method of placement for bulk materials, in cases when circumstances make formwork overly time consuming or simply impractical. In general, the method of installation will depend on cost and accessibility.

2. INSULATING

Another product that we supply is the castable refractories that are low density. These insulating castables pose very low thermal conductivity and are utilized for either high temperature face work or when used for a backup lining, which is found behind dense castables or brick work. Here, the insulating castables are able to decrease the lining’s overall density or the cold face temperature. Their strength, which ranges from low to medium, is based on the fact that their density is low and is the main reason that they are not resistant to abrasion. They are most suitable where they do not have to stand up to much wear and tear.

3. LOW CEMENT

This type of refractory castable is prepared with a lower amount of cement than the standard dense castable is normally created with. Low cement castable refractories fluctuate in alumina content, which provides exceptional physical properties, including low porosity, great abrasion properties and high vigour. These products will commonly necessitate installation that is controlled, however, the big advantage of low cement castables is that they are easily pumped into position, and some may not require vibration, because they are free flowing.